| Instrumentation Cables | ||||||||||||||

|

||||||||||||||

Instrumentation Cables

Instrumentation Cables

600/1000V twisted pair control cables to AS/NZS 2373

Application

These cables are used in control, supervisory, protection and instrumentation circuits or used as pilot cables.

They commonly occur in power stations, substations or in industrial applications.

Standard

AS/NZS 2373

Rated voltage

600/1000V

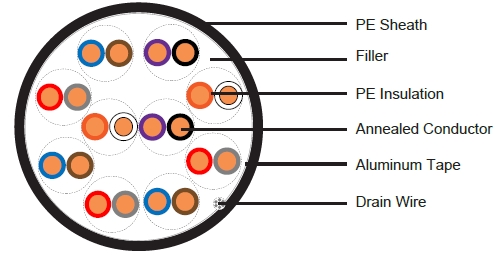

Construction

Conductor: Single wire plain annealed copper, complying with AS/NZS 1125.

Insulation: PE complying with AS/NZS 3808.

Lay-up: An adequate number of separate, identifiable lengths of lay of twisted pairs shall be used to

minimize crosstalk.

Fillers and Tapes: Fillers, binder and wrapping tapes shall be of suitable non-metallic materials. Collective

screen: Copper tape or aluminum (min. thickness of 0.07mm) or aluminum/polyester tape (min. thickness of

0.023)

Drain wire: Tinned copper consisting of seven wires of at least 0.25 mm nominal diameter for aluminum tape.

Armor (optional): Steel tape or steel wire complying with AS/NZS 5000.1

Sheath: PE, 4V-75 or HFS-75-TP complying with AS/NZS 3808.

Parameter

Nominal cross- sectional area of conductor (mm2) |

Nominal diameter (mm) |

Insulation thickness (mm) |

Sheath thickness (mm) |

Maximum d.c. resistance at 20oC (Ω/km) |

|

|---|---|---|---|---|---|

0.64 |

0.90 |

0.8 |

10-pair |

1.8 |

28.3 |

30-pair |

1.9 |

||||

50-pair |

2.1 |

||||

100-pair |

2.4 |

||||

1.0 |

1.13 |

0.8 |

10-pair |

1.8 |

18.1 |

30-pair |

2.0 |

||||

50-pair |

2.2 |

||||

100-pair |

2.5 |

||||

| 1.27 | 1.27 | 0.8 | 10-pair |

1.8 |

14.3 |

30-pair |

2.1 |

||||

50-pair |

2.2 |

||||

100-pair |

2.6 |

||||

| 1.5 | 1.38 | 0.8 | 10-pair |

1.8 |

12.1 |

30-pair |

2.1 |

||||

50-pair |

2.2 |

||||

100-pair |

2.6 |

||||

Other size could also be provided upon request.

Lay-up formation

Cable size |

No. of pairs in centre and successive layers |

|||||

|---|---|---|---|---|---|---|

Centre |

1st |

2nd |

3rd |

4th |

5th |

|

10-pair |

2 |

8 |

- |

- |

- |

- |

30-pair |

4 |

10 |

16 |

- |

- |

- |

50-pair |

3 |

9 |

16 |

22 |

- |

- |

100-pair |

2 |

8 |

14 |

20 |

25 |

31 |

Color Code

When the twisted pairs in the cable are identified by colors, the color coding of the pairs shall progress in

sequence from the center of the cable as given in the following table. alternatively, each pair may contain a

black and a white insulated core. One or both cores in each pair shall be numbered in a contrasting color. The

numbering of pairs shall progress in sequence from the center of the cable.

Centre or Layers |

Insulation color |

||||||

|---|---|---|---|---|---|---|---|

Pair 1 |

Pair 2 |

Pair 3 |

Pair 4 |

Pair 5 |

Pair 6 |

Last Pair |

|

1-pair |

Orange- |

|

|

|

|

|

|

2-pair |

Orange- |

Violet-black |

|

|

|

|

|

3-pair |

Orange- |

Red-grey |

Violet-black |

|

|

|

|

4-pair |

Orange- |

Red-grey |

Blue-brown |

Violet-black |

|

|

|

Layers |

Orange- |

Red-grey |

Blue-brown |

Red-grey |

Blue-brown |

* |

Violet-black |

*Pair colors shall repeat from red-grey